SLT bearings from CeramicSpeed

CeramicSpeed have released details of a bearing technology claiming to be maintenance free and highly durable. Solid and baked ‘SLT’ bearings.

>>> Does jet washing really wreck your bike?

It looks kind of like a hybrid of bushing material sitting inside a cartridge bearing housing. But there’s more to it than that we suspect.

A key line in the press release explains: “CeramicSpeed SLT Bearings contain a polymer matrix saturated with lubrication oil. The matrix retains oil right on the functional surfaces of the bearing under the harshest of conditions while at the same time preventing contaminants from entering the bearing.”

>>> How to service frame bearings and pivots

CeramicSpeed SLT press release

CeramicSpeed Predicts The Future: Off-Road Bearings Will Be Solid And Baked

Breakthrough product ‘SLT Bearings’ set to revolutionise the off-road bearing market

3rd July, 2018 – Holstebro, Denmark: After more than 18 months of rigorous development and testing, Danish drivetrain efficiency and ceramic bearing specialists, CeramicSpeed, unveil SLT Bearings – the breakthrough bearing product that carries the potential to revolutionise the off-road bearing market.

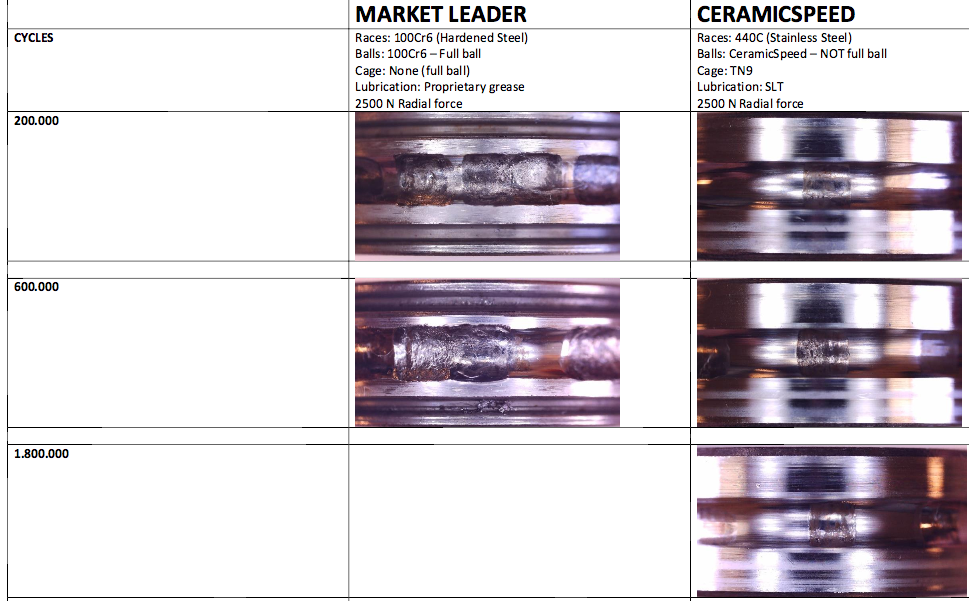

SLT Bearings are a product developed entirely in-house with combined efforts from the sport and industrial division of CeramicSpeed. The product, described as a solid lubrication bearing that is maintenance free, highly durable and extremely protective against contaminants, has demonstrated longevity benefits three times greater than the market leader for off-road pivot bearings.

As CeramicSpeed ramp up their efforts in the off-road cycling market, the company believes their breakthrough with SLT Bearings will make maintenance-free bearings the go-to bearing for the high-end off-road scene.

“We’re very excited about this product and strongly believe it has the potential to revolutionise the off-road bearing market,” said Martin Banke, Executive Vice President of CeramicSpeed. “For a long time, we have been presented with the longevity challenges that face bicycle and component manufacturers in the off-road scene. SLT Bearings can overcome those challenges with impressive results and a unique maintenance-free characteristic.”

Earlier this year CeramicSpeed emphasised their off-road efforts by adding a proprietary pivot bearing test machine to their extensive list of bespoke testing equipment. The test machine, which can be seen in action HERE was designed to capture longevity data of pivot bearings while simulating real-world loading/force conditions.

Having concluded the most recent round of longevity testing, CeramicSpeed SLT Bearings have outperformed the market leader for off-road pivot bearings, by as much as three times. Testing results, performed with 2500Nm of radial force, show the extraordinary differences in wear between CeramicSpeed SLT Bearings after 1.8 million cycles and a market leader at 600,000.

“Our development of SLT Bearings has received overwhelming interest from our OEM partners. The demand for a high performing and more durable bearing for pivots has confirmed and validated our investment in using this technology for this application.” said Jonathan Small who leads CeramicSpeed’s implementation of SLT Bearings for the off-road market.

CeramicSpeed Bearings have been proven throughout the elite off-road scene for several years with exceptional performances at multiple UCI MTB World Cup and World Championships, and the Cape Epic among others.

As further testament to the longevity of CeramicSpeed’s new SLT Bearings, CeramicSpeed’s industrial division has been utilising the same technology with impressive results. CeramicSpeed hybrid bearings with SLT have outperformed standard bearing solutions on service life by eight times or more, in conditions that are normally unsuitable for any bearing. Running partly submerged, running under daily exposure to splash water and detergents, and, in one real life test, in an acetone solution.

CeramicSpeed SLT Bearings contain a polymer matrix saturated with lubrication oil. The matrix retains oil right on the functional surfaces of the bearing under the harshest of conditions while at the same time preventing contaminants from entering the bearing. The manufacturing process of CeramicSpeed SLT Bearings requires the baking the bearings in hot ovens.